Laser cutting

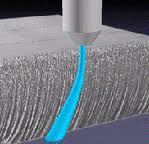

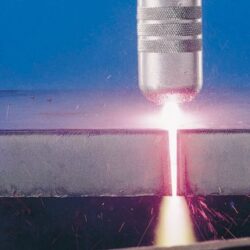

CO2 laser cutting is the most accurate, the fastest, and often the most economical method of steel and stainless steel processing. When black steel is cut in the protective atmosphere of nitrogen gas, a clean cut without the oxide film is produced, allowing the parts to be painted or galvanized without further treatment. Gas lasers can also cut non-ferrous metals – aluminum, copper, brass, or titanium with equal efficiency and accuracy, but due to the reflections there’s a risk of damaging the lens and mirror systems, therefore many are avoiding using gas lasers for cutting these materials; they use abrasive water jet cutting or the new generation fiber laser instead.

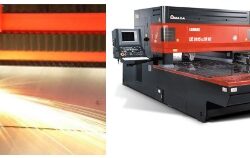

We are operating CO2 laser Bystar 3015 with 4.4 kW power source Bylaser 4400, manufactured by BYSTRONIC, one of the best-known laser manufacturers in the world, and that is the optimal choice for high precision cutting of various thicknesses of steel and stainless steel sheets, as well as tubes and profiles.

Bysoft software allows processing DXF files easily and quickly and allows to prepare cutting programs and to save raw materials.

Technical features of CO2 laser Bystar 3015 4.4 kW:

- Sheet cutting range: 3048 ×1524 mm(two changeable tables);

- Maximum sheet thickness:25 mm(steel),20 mm(stainless steel);

- Maximum tube diameter:315 mm;

- Maximum tube length:3 m;

- Positioning speed (x and y axes simultaneous):113 m/min;

- Acceleration:4.5 m/s²;

- Positioning accuracy: +/-0.1 mm/m;

- Repeatability: +/-0.05 mm/m.